Optimising the Metal Industry with NIRAFON®

Main advantages of the NIRAFON® in the metal industry

In the metal industry, NIRAFON® acoustic cleaning systems provide a range of advantages. Applications boost productivity, cut down on expensive and risky manual cleaning, minimize plant downtime, protect equipment from damage during cleaning, and improve heat transfer efficiency.

Product benefits

-

Continuously clean filter bags, longer bag lifetime.

-

Considerably lower air consumption for keeping clean bag filters.

-

Less electricity use of fans, thanks to lower pressure difference and reduced need for suction.

-

Improved heat transfer.

-

Can be used in high temperatures.

-

Eliminates the risk of plant downtime.

-

Ensure sthe correct operation of SCR systems, while maintaining high plant efficiency.

-

Minimize damages due to cleaning.

-

Acoustic horns are best in cleaning dry, loose, powder-like deposits.

The NIRAFON® system can be used in combination

with existing cleaning system

Saving energy and money

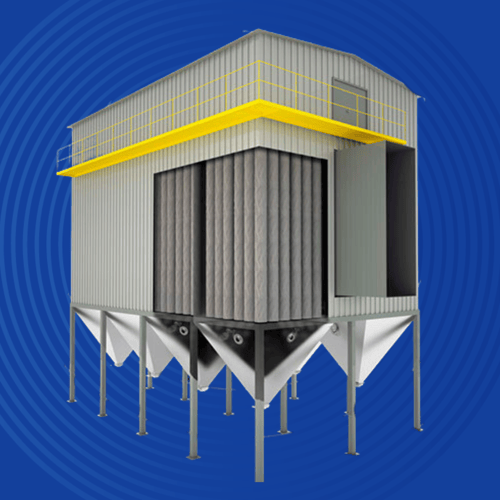

The Baghouse system excels over compressed air pulse systems (Jet Pulse) with continuous full-bag cleaning, lower air consumption, reduced fan electricity usage, high-temperature suitability, and no bag wear or fiber abrasion.

Cleaning without damaging

ESP (Electrostatic Precipitator) eliminates rapper system weaknesses through continuous prevention of particle buildup, more thorough cleaning extending to hoppers and walls, avoiding mechanical stress and damage, eliminating hopper blockage, ensuring steady material flow, and maintaining low maintenance costs.

Applications

-

Bagfilters

-

ESP

-

Heat recovery boilers

-

Cooling towers

-

SCR